What is Industrial Packaging and Its Importance in Modern Business

In today's fast-paced business environment, industrial packaging plays a crucial role in ensuring products reach their destinations intact. Expert John Smith, a consultant in the packaging industry, emphasizes, "Effective industrial packaging can make or break your supply chain." This insight highlights the significant impact of packaging on overall efficiency.

Industrial packaging is more than just a method of containment. It influences storage, transportation, and even marketing. Companies face challenges in choosing the right materials and designs that optimize protection and cost-effectiveness. Functional packaging must balance durability with sustainability, pushing businesses to reflect on their values.

Despite advancements, many businesses still struggle with outdated packaging practices. This can lead to damage, increased costs, and wastage. As organizations innovate, they must rethink their approach to industrial packaging to enhance efficiency. Adopting modern solutions is essential for staying competitive and protecting the environment.

Definition of Industrial Packaging and Its Key Characteristics

Industrial packaging is a specialized form of packaging primarily designed for the protection and transportation of goods. Unlike retail packaging, it focuses on bulk, ensuring items reach their destination intact. This type of packaging often utilizes materials like cardboard, metal, or plastic, tailored to meet the needs of specific industries. For example, heavy industrial machinery may require reinforced crates, while fragile goods necessitate cushioned interiors.

Key characteristics of industrial packaging include durability and strength. It must withstand the rigors of shipping, including stacking and vibrations. Moreover, industrial packaging often includes standardized sizes for optimal space utilization. Additionally, the design may prioritize ease of handling, allowing for mechanical lifting and efficient storage. Despite its importance, some businesses overlook the significance of sustainable materials. Rethinking the materials used can enhance environmental responsibility.

Another consideration is cost efficiency. While it's tempting to minimize spending, cutting corners on packaging can lead to damage costs. Finding the right balance between cost and quality can be challenging, yet critical. Understanding the unique requirements of your products can guide better packaging choices. Ultimately, focusing on the nuances of industrial packaging can lead to improved operational efficiency and customer satisfaction.

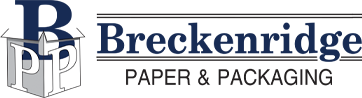

Types of Industrial Packaging Materials and Their Uses

Industrial packaging plays a pivotal role in modern business. Various materials are used to meet distinct needs. Common types include cardboard, plastic, and metal. Each material serves unique purposes in the supply chain. Cardboard is often favored for its recyclability and ease of printing. According to a report by Smithers Pira, the global market for cardboard packaging is projected to reach $250 billion by 2024.

Plastic packaging continues to see significant use due to its versatility. It can be molded into nearly any shape and is lightweight. However, sustainability concerns arise from plastic's environmental impact. A National Geographic study indicates that approximately 91% of plastic is never recycled. This raises serious questions about its long-term viability in packing solutions.

Metal packaging, often used in food and beverage industries, provides durability and product protection. Aluminum cans, for instance, keep contents fresh. The global metal packaging market was valued at over $120 billion in 2022. Yet, the energy-intensive process of metal production creates environmental challenges. As businesses navigate these options, they must reflect on sustainability and long-term goals.

The Role of Industrial Packaging in Supply Chain Management

In today's fast-paced business environment, industrial packaging plays a vital role in supply chain management. Proper packaging is more than mere aesthetics. It is critical to protecting products during transit. Think of fragile items, such as glass or electronics. Without adequate packaging, they become vulnerable to damage. This can lead to financial losses and customer dissatisfaction.

Moreover, efficient packaging helps optimize logistics. It simplifies loading and unloading operations. When packages are designed thoughtfully, space is conserved. This effect can lower transportation costs significantly. However, companies often overlook the importance of sustainability in packaging. Using excessive materials can be wasteful and harmful to the environment. It's a balancing act between protection and eco-friendliness.

Some businesses still struggle with the complexity of industrial packaging choices. Confusion around materials and designs leads to inconsistent results. Not all packaging solutions fit every product type. Understanding product-specific needs is crucial. This requires ongoing evaluation. Companies must be willing to adapt their strategies. In this ever-evolving market, flexibility is essential to stay competitive.

Benefits of Effective Industrial Packaging for Modern Businesses

Effective industrial packaging plays a vital role in modern businesses. It goes beyond protecting products; it enhances brand identity. Well-designed packaging attracts customers and communicates quality. Packaging can be the first impression a potential buyer has. It should not be overlooked or underestimated.

There are tangible benefits to investing in good packaging. It reduces damage during transportation. A strong package can prevent costly losses. Packaging also aids in inventory management. It allows easy stacking and storage. However, some companies may neglect this area, leading to inefficient operations.

Additionally, sustainable packaging is becoming increasingly important. Consumers are more environmentally conscious. They prefer brands that show responsibility. If a business fails to adapt, it risks losing customers. Balancing cost and effectiveness in packaging can be challenging. Companies need to continually reassess their strategies.

Importance of Industrial Packaging in Modern Business

Future Trends in Industrial Packaging and Sustainability Efforts

Sustainability is a growing priority in industrial packaging. Many companies are shifting toward eco-friendly materials. Biodegradable plastics and recycled materials are gaining traction. These options can reduce waste and lower carbon footprints. However, the transition can be challenging. Cost and supply chain disruptions often complicate these efforts.

The design of packaging is also changing. Companies are exploring minimalist designs to cut material use. Streamlined packaging can minimize production and transportation costs. Yet, not all companies fully embrace these strategies. Some struggle with balancing functionality and sustainability. The ideal solution often remains elusive.

Looking ahead, technology plays a crucial role. Innovations like smart packaging can enhance efficiency. They track products in real-time, reducing losses. Nevertheless, implementing these technologies is not simple. High initial costs and the need for training can hinder adoption. It's a complex journey where businesses must evaluate their commitment to sustainability.

Related Posts

-

What is Poly Packaging and How It Benefits Your Business in 2023

-

How to Choose the Best Packing Paper for Your Shipping Needs

-

How to Choose the Right Packaging and Supplies for Your Business Needs

-

Top Packing and Shipping Supplies Every Small Business Needs for Success

-

2025 Top 5 Business Packaging Solutions Driving Sustainability and Cost Efficiency

-

What are the Best Packaging Options for Your Products in 2023